Quieter, More Comfortable

What is it? What are its Properties? Where is it used?

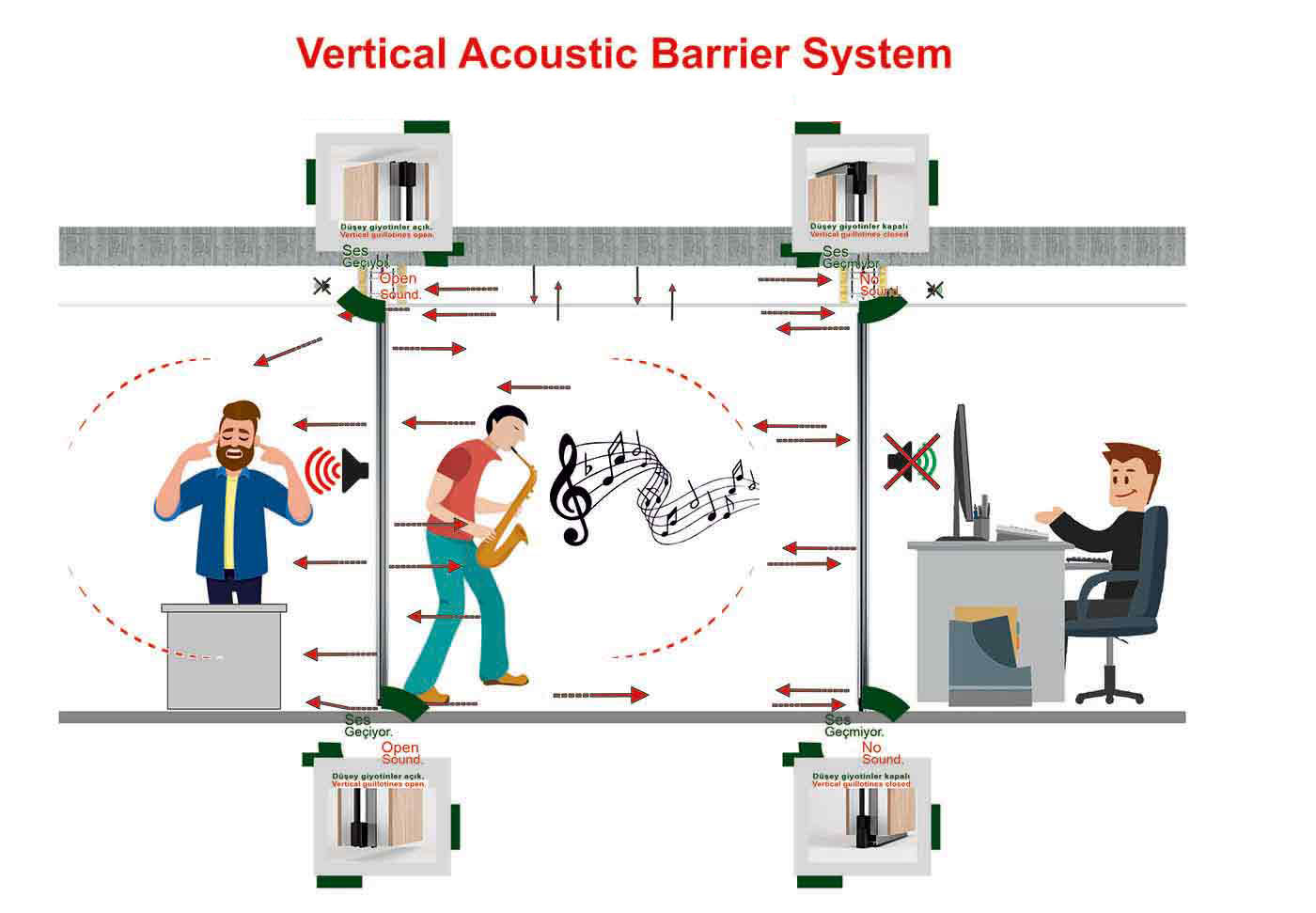

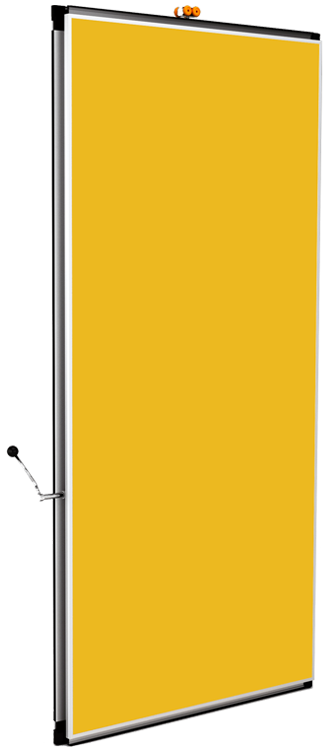

Panelite movable partition wall system is Turkowall's system with superior features. Panelite is used in places that require high levels of sound insulation. It offers excellent ease of use, offers a high level of acoustic and thermal insulation. The assembled panels are fixed horizontally with the help of rubber guillotine profiles. With the guillotine system in each panel, the insulating profiles close the joints in the floor and ceiling and obtain an insulated wall.

The insulation materials used in the panel vary depending on the needs of the space and the requirements of the user. By using materials with superior technical properties, the insulation values reach the maximum. The Panelite system can be safely used in conferences, meetings, weddings, ballrooms, invitation rooms, and educational institutions.

Like other systems, the system panels move within the standard rail fixed to the ceiling. The system works manually. Depending on the situation, single or double rollers may be preferred. However, when the panel dimensions are large and the insulating material to be used in the panel is taken into account, it is more advantageous to use the double roller system. It is possible to store all the panels inside or outside the space in the desired area or even in a hidden section.

Flexible Use

Comfort

Acoustic Space

Panelite is a mobile system that is used in conference rooms, wedding rooms, meeting and organization rooms, educational institutions, and many other places. It offers a sensible use of space, which is created with movable partition systems. The manual scissor system closes the gaps in the rail and the floor with the guillotines coming out of the panels at the top and bottom. Soundproofing is provided and guarantees a holistic space. It is a movable partition wall system with high product quality and insulation values. It is a movable partition wall solution consisting of independent modules that provide sound insulation by being perfectly aligned when the system is closed.

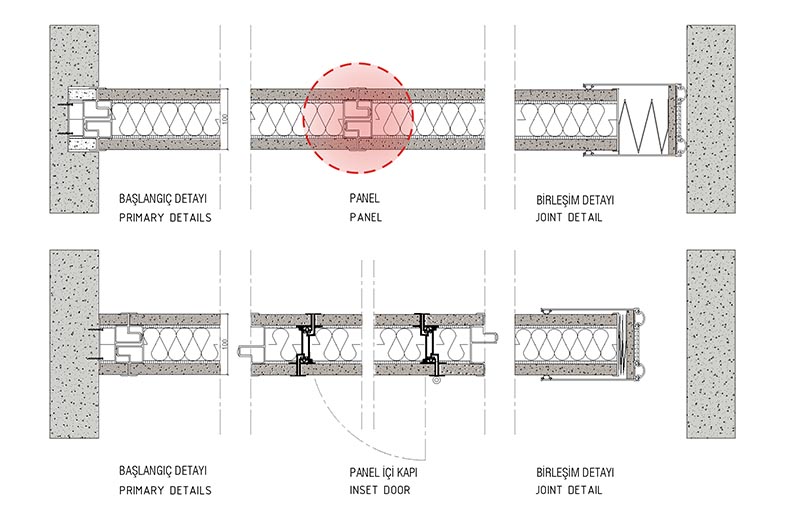

Our Panelite movable wall system has a profile-protected and connected joint detail option.

The Panelite movable partition system promises a high level of acoustic comfort. The rubber wicks, which are integrated into the specially developed vertical and horizontal joint profile, guarantee advanced sound insulation. Guarantees sound insulation of up to 60 decibels if other components in the space are compatible.

Even the standard version of our systems has more acoustic characteristics than its counterparts. Depending on the intended use and your request, we offer standard, high and advanced sound levels.

Acoustic Elements

High-Density Rockwool (150 kg/m3): Standard

Soundproofing barrier (3 mm on both insides): Standard

Soundproofing barrier (3 mm on both insides): Optional

Acoustic junction wedge (4 corners on each panel): Standard

Acoustic wooden surface (Special perforated or striped): Optional

Acoustic fabric surface (with acoustic sponge): Optional

Vertical sound insulation barrier (Guillotine): Standard

Horizontal concave-convex aluminum caps: Standard

Horizontal concave and convex insulation cords: Standard

Sound insulation level: 39 dB and 60 dB

Note: The most important factor that determines the sound insulation value is the sound coefficient of the other components of the space.

Panelite movable wall system is Turkowall's system with superior features. Panelite is used in places that require high levels of sound insulation. It offers excellent ease of use, offers a high level of acoustic and thermal insulation. The assembled panels are fixed horizontally with the help of rubber guillotine profiles. With the guillotine system in each panel, the insulating profiles close the gaps in the floor and ceiling and obtain an insulated wall. The insulating materials used in the panel will vary based on the requirements of the room and the needs of the user. By using materials with superior technical properties, the insulation values reach the maximum. The Panelite system can be safely used in conferences, meetings, weddings, ballrooms, invitation rooms, and educational institutions.

|

|

|---|---|

| Semi-Automatic Shutdown | |

| Telescopic Panel | |

| Vertical Guillotine Lock | |

| In-Panel Door (Optional) | |

| Profiled Panel Thickness | 10cm |

| Jointed Corner Panel Thickness | 12cm |

| Maximum Height | 1200cm |

| Minimum Width | 80cm |

| Max Width | 135cm |

| Single reel/rollerr | |

| Double reel/rollerr | |

| Sound Insulation Values | 39-60 (dB) |

| Weight per M'² | 35-60 kg |

| Anodized Static Painted Aluminum Profile | |

| In-panel glass modules | |

| Door glass modules | |

| Wood surface coating | |

| Fabric surface coating | |

| Glass surface coating | |

| Password or card pass system | |

| Outdoor parking option | |

| Acoustic comfort enhancement option | |

| Acoustic barrier | |

| Insulation Tapes |

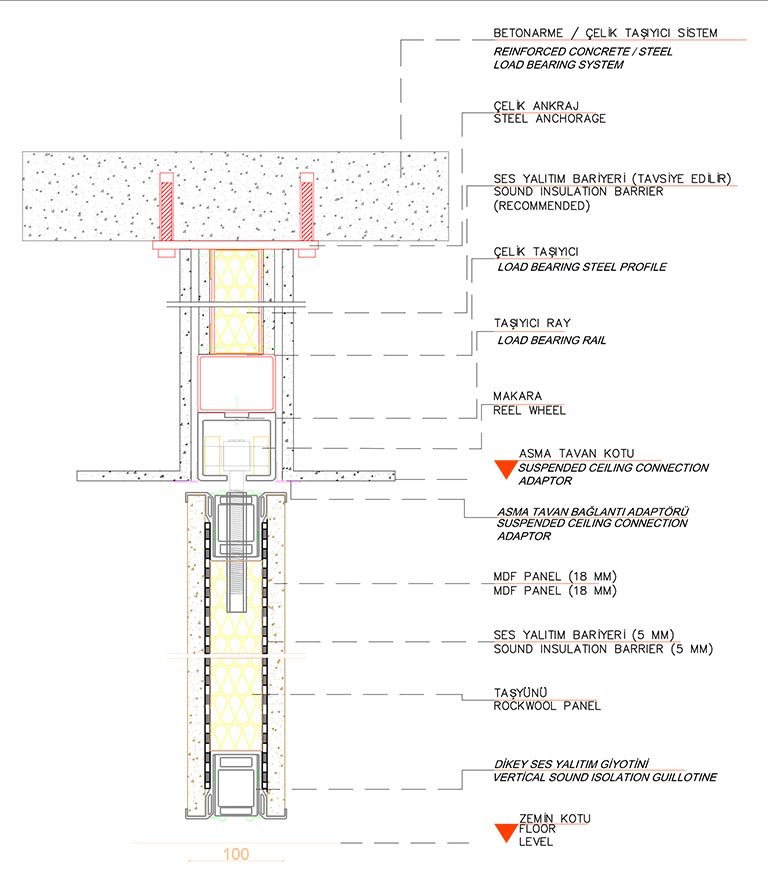

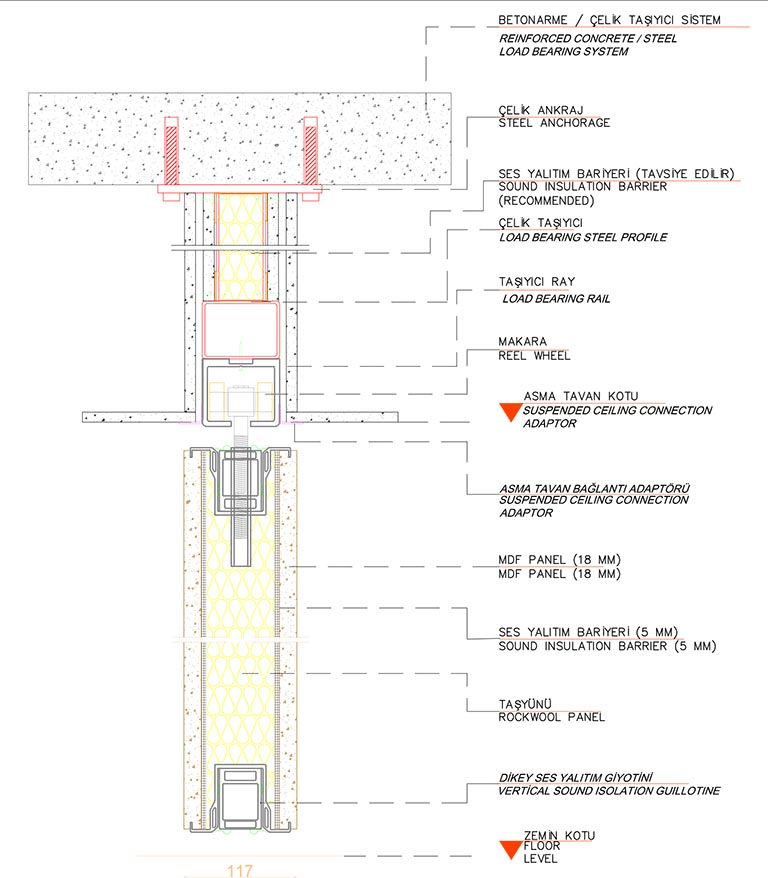

You can download the technical design tools, plans, elevations, and system sections of the Panelite Manual Guillotine Partition Wall system in CAD and PDF formats and easily use them in your projects.

Panelite is a mobile system that is used in conference rooms, wedding rooms, meeting and organization rooms, educational institutions, and many other places. It offers a sensible use of space, which is created with movable partition systems. The manual scissor system closes the gaps in the rail and the floor with the guillotines coming out of the panels at the top and bottom. Soundproofing is provided and guarantees a holistic space. It is a movable partition wall system with high product quality and insulation values. It is a movable partition wall solution consisting of independent modules that provide sound insulation by being perfectly aligned when the system is closed.

Download PDF

Download PDF